Date: April 24, 2024 Update: April 25, 2024

On April 22, 2024, a press activity was conducted by the Ministry of National Defence Press and Public Relations Consultancy to introduce the İstanbul Naval Shipyard Command, the first ship of the İSTİF Class Frigate Project, TCG İstanbul Frigate (F-515), and the Naval Forces Command Design Project Office (DPO) to the Turkish and international public. TCG İstanbul Frigate (F-515), designed by the Naval Forces Command Design Project Office (DPO) with domestic capabilities and constructed at İstanbul Naval Shipyard Command, was delivered on January 19, 2024. Established on March 12, 2004, as the MİLGEM Project Office within İstanbul Naval Shipyard Command, the Design Project Office (DPO) has been operating in its new building since September 2015.

During the event, which was attended by approximately 40 reporters, İstanbul Naval Shipyard Commander Rear Admiral (RDML) Recep Erdinç YETKİN provided a comprehensive briefing introducing the İstanbul Naval Shipyard Command at the Design Project Office (DPO) Directorate building. Following this, Assoc. Prof. Captain (CAPT) Hakan UÇAR, the Director of the Naval Forces Command Design Project Office (DPO), conducted a presentation on the capabilities of the DPO and provided information on the MİLGEM, İstanbul-class Frigate, TF-2000 AAW (Anti-Air Warfare) Destroyer, and National Aircraft Carrier Projects.

Following the presentation, the reporters were taken to the second floor of the building to visit the Hull and Machinery Design Chief Engineering section, where the design works for the TF-2000 and National Aircraft Carrier Projects prepared by DPO engineers were showcased. During the tour, the press members were briefed, and their questions were answered by DPO Director Hakan UÇAR, DPO Hull Design Branch Manager Lieutenant Commander (LCDR) Mustafa KÜLTÜR, and DPO Machinery Design Branch Manager Lieutenant Commander (LCDR) Mustafa Güntaç TOSUN regarding the projects. After the DPO Directorate building visit, a lunch break was provided during the press activity.

.jpg)

After lunch, the reporters visited the Engine Factory, where maintenance is conducted at the manufacturer level for diesel engines, and the Cannon Factory, where maintenance, repair, and overhaul work for guns ranging from 20mm to 76mm/62 Compact main guns in inventory are performed. The Cannon Factory possesses the Manufacturer Level Maintenance/Overhaul (W6) capability for 76mm/62 Compact main guns. Additionally, the Engine Factory has the Manufacturer Level Maintenance/Overhaul (W6) capability for MTU 16V956TB91 series diesel engines found in DOĞAN Class Fast Attack Crafts, as well as for MTU16V595TE90 Diesel Engines used in KILIÇ-I/II Class Fast Attack Crafts and ADA Class Corvettes.

In the Engine Factory, there were also two 600hp AZRA Marine (LEVEND) Engines, newly produced by BMC Power Company. We learned that these two engines, tests of which were completed at BMC Power facilities, will soon be integrated into a Tugboat as main engines and begin sea trials. In preparation for the integration of the LEVEND Diesel engines, the old engines on the Tugboat have been removed, and necessary preparations have been made. As part of this process, the production of necessary subsystems, such as new shafts, propellers, and bearings, has been carried out at the shipyard. It has also been evaluated that LEVEND can serve as auxiliary machinery on larger vessels.

Subsequently, we proceeded to the dry dock (measuring 300m x 70m), where repair activities were underway. Here, we observed the Savarona Yacht, inherited from Mustafa Kemal ATATÜRK, undergoing repair, as well as the second ship of the Offshore Patrol Vessel Project, KOÇHİSAR (P-1221), and the second ship of the PN-MİLGEM Project, the PNS KHAIBAR (282) Corvette under construction at the İstanbul Naval Shipyard. We were briefed on the current progress of the work, and it is expected that both ships (Savarona and 282) will be launched within a month. The repairs to the hull and deck of the Savarona Yacht are largely completed, and it is expected to resume sailing with Turkish Navy personnel in 2024 summer. The yacht will initially serve as a training vessel and is also planned to conduct port visits nationwide to promote maritime activities among the public.

The first ship of the Offshore Patrol Vessel Project, AKHİSAR (P-1220), constructed by the main contractor ASFAT Inc., and the first ship of the PN-MİLGEM Project, PNS BABUR (280), also built by the main contractor ASFAT Inc., were waiting for us moored next to TCG İstanbul Frigate, which was the final stop of the press activity in the dockyard. AKHİSAR (P-1220) was equipped with the 76mm/62 National Naval Gun produced by MKE Inc. last week. PNS BABUR (280), Türkiye's largest and most significant export in naval systems, was delivered in a ceremony held on September 23, 2023. The training activities of the PNS BABUR Corvette are continuing, and it successfully completed firing tests with the 76mm/62 Super Rapid main gun last week, hitting the target on its first shot.

.jpg)

Our visit to the first indigenous frigate of our country, the İSTİF Class TCG İstanbul Frigate (F-515), designed by the Naval Forces Command Design Project Office (DPO) with domestic capabilities and constructed at İstanbul Naval Shipyard Command with an 80% local content rate, began with a welcoming speech by the Ship Commander, Captain (CAPT) Kemal ALGIN. After that, the TCG İstanbul Weapons Officer, Lieutenant Commander (LCDR) Gökhan ŞAHAN, delivered the TCG İstanbul Press Briefing. The TCG İstanbul Frigate, which started its construction on February 4, 2020, after the project commenced on September 27, 2019, was launched on January 23, 2021, and commissioned into service on January 19, 2024. It measures 113.27 meters in length and 14.42 meters in width and has a displacement of 3,171 tons (max). It can cruise 5,700 nautical miles (10,545 kilometers) at optimal cruising speed.

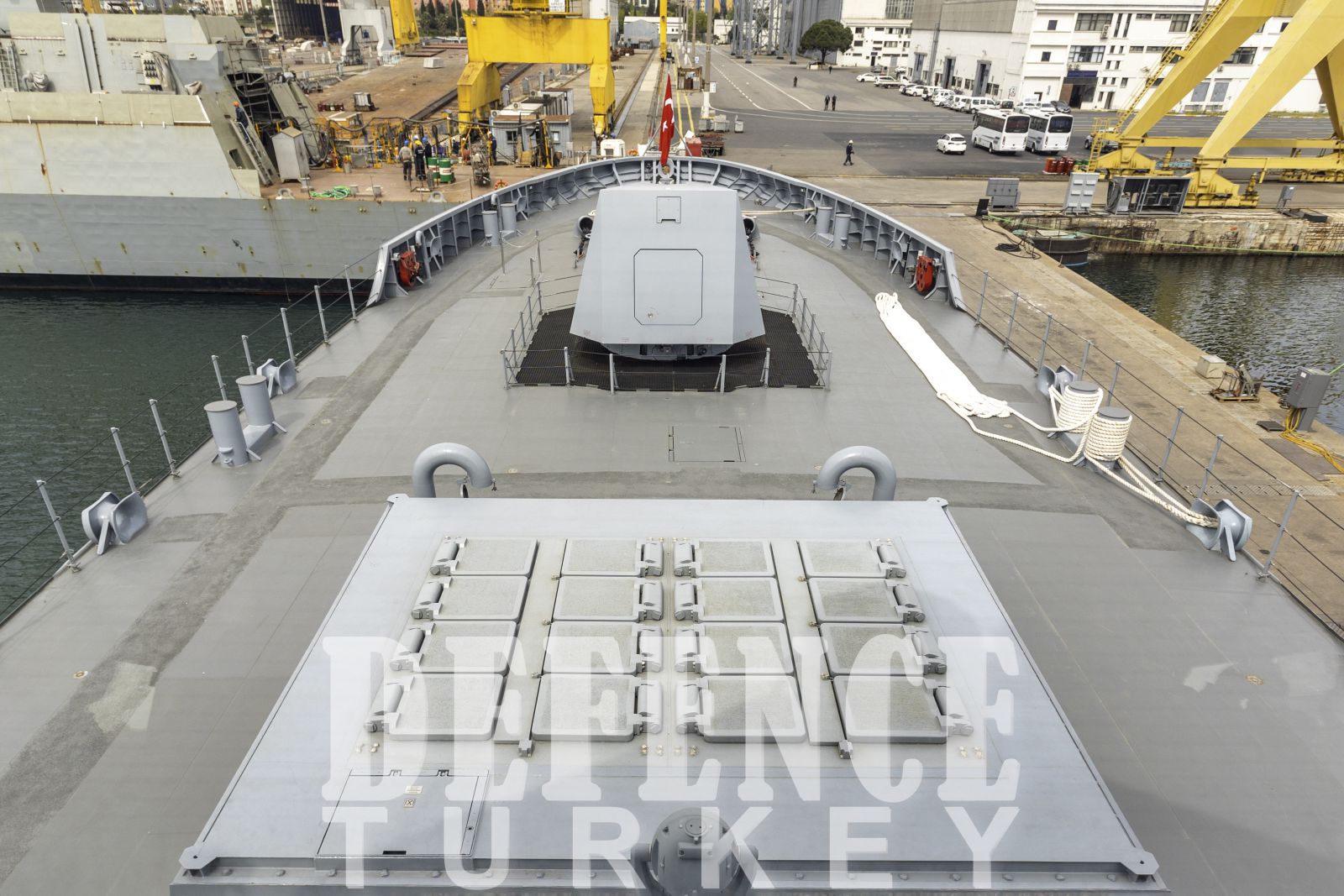

After the briefing, we toured the Combat Information Center (CIC) and the Bridge in groups. Additionally, we were informed about the 76mm/62 Super Rapid gun at the bow and the 16-cell tactical length National Vertical Launching System (MİDLAS), which is an improved variant of the Mk-41VLS with additional requirements and feedback from the Turkish Naval Forces. The CIC layout of TCG İstanbul Frigate was considerably spacious compared to the CIC layout of ADA Class Corvettes and GABYA Class Frigates.

The ship's CIC, which utilizes the Network-Centric ADVENT Combat Management System (CMS), is equipped with 14 Operator Consoles (OPKON), which control the 16-cell MİDLAS VLS, HİSAR-D/RF Anti-Air Missiles, 35mm GÖKDENİZ CIWS, 76mm/62 Super Rapid Main Gun, and 25mm Stabilized Gun (STOP) Systems. Additionally, there was a Sonar Console, an ATMACA Anti-Ship Missile Console (which can be operated from one of the Operator Consoles in case of malfunction), and a Navigation Plot Table (allowing real-time tracking of the ship's position on an electronic map). As the first ship equipped with 16 ATMACA AShMs in the Turkish Naval Forces inventory, TCG İstanbul Frigate is equipped with Link-11, Link-16, and Link-22 Tactical Data Link Systems. The personnel we spoke with in the CIC emphasized their pride in operating national systems.

As part of the acceptance process of the tactical length MİDLAS VLS (for self-defence purposes) on TCG İstanbul Frigate, the first firing test was conducted using the HİSAR-D RF Calibration Test Missile off the coast of Sinop on March 10, 2024. By the end of 2024, a series of firing tests will be conducted using the HİSAR-D RF Seeker Guided Test Missile and the Warhead Test Missile, and the entire system will be accepted. The sister ships of TCG İstanbul, which are still under construction, will be armed with the strike length MİDLAS VLS (for SİPER-D, ATMACA, and GEZGİN Guided Missiles).

You can find our comprehensive news article in the latest issue of Defence Turkey Magazine, with detailed information from the press activity and complemented by striking photos taken by Cem DOĞUT.

Headlines of the special information we will provide in our article:

· The TF-2000 AAW Destroyer, with a length of 149 meters, width of 21.3 meters, a draft of 5.75 meters, and displacement of 8,300 tons, will be equipped with a Combined Diesel or Gas (CODOG) configuration main propulsion system consisting of 2 LM2500 Gas Turbines and 2 Diesel Engines. It will be capable of a maximum speed of 26 knots and operating in Sea State 5. The Preliminary Design of the TF-2000 AAW Destroyer has been completed. Due to design changes, model tests are planned to be conducted again in collaboration with İstanbul Technical University during the summer months of this year.

· Similar to the previous longer TF-2000 design, a split funnel was again chosen for the TF-2000 AAW Destroyer. A dual funnel (split funnel) with a large surface area is preferred to allow better air intake, improved cooling, and further thermal signature reduction. We learned that the two rectangular structures immediately in front of the funnels are ventilation intakes, not allocated areas for additional VLS as previously predicted.

· The TF-2000 AAW Destroyer will feature 32-cell VLS at the bow and 64-cell VLS launchers amidships, totaling 96 cells for MİDLAS VLS. The decision to use 96 cells has been finalized. The number of Quad-Pack capable cells in the MİDLAS VLS, which is expected to be Strike length, will be determined over time.

· The ÇAFRAD (Multi-Function Phased Array Radar) AESA Radar System antenna arrays will be integrated into the ship both at the bow and stern in separate compartments. The choice of separate array/mast placement is preferred to enable unrestricted 360-degree scanning, target detection, and tracking without any visual obstruction. In the new ÇAFRAD System Configuration, two fixed S-Band Long-Range Radar (UMR) arrays are placed on the ship's superstructure at the bow (starboard and port sides), while the other two fixed arrays are mounted on the mast at the stern. In addition to its early warning capability, UMR will also provide guidance for HİSAR and SİPER missiles to the target. The phased array antennas of the X-Band Multi-Function Radar (ÇFR), which will focus solely on surface engagement, are located on the integrated main mast. The standard detection range for ÇAFRAD is expected to be 450 km+, with a target detection range of 750 km at full power.

· The first TF-2000 AAW Destroyer will be constructed at İstanbul Naval Shipyard Command with a local content ratio of 85%.

· The National Aircraft Carrier, planned to have a total length of 285m, width of 72m, draft of 10.1m, and displacement of 60,000 tons, will be equipped with a COGAG-type Main Propulsion System consisting of 4 LM2500 Series Gas Turbines. It will also feature a STOBAR (Short Take-Off, Barrier-Arrested Recovery) aircraft launch and recovery system. The National Aircraft Carrier will achieve a maximum speed of 25 knots unrestricted and have a cruising range of 10,000 nautical miles without refueling.

· It is not planned to receive technical support from a foreign company for the National Aircraft Carrier, which will be entirely designed by the Design Project Office Directorate and constructed by Turkish engineers and workers at İstanbul Naval Shipyard Command. Within the Design Project Office (DPO) Directorate, a 110-person Aircraft Carrier Working Group has been established, and the team has begun conceptual design by dividing into subgroups according to expertise.

.jpg)

· The National Aircraft Carrier, aimed at enhancing the deterrence and effectiveness of the Turkish Naval Forces, will feature 2 take-off (highlighted in yellow) and 1 landing runway, along with 3 taxiways.

· The self-defence of the National Aircraft Carrier will be provided by a 32-cell MİDLAS VLS launcher and 4 GÖKDENİZ CIWS.

· The National Aircraft Carrier will be capable of accommodating a total of 50 aircraft, with 20 on the flight deck and 30 in the hangar section (indicating the potential for this number to increase). Work is underway to enable the unrestricted operation of HÜRJET, ANKA-III, KIZILELMA, and BAYRAKTAR TB3 UCAVs on the National Aircraft Carrier. Weekly meetings are held with DPO personnel to discuss how these aircraft from both TUSAŞ and BAYKAR will be used on the National Aircraft Carrier and what modifications need to be made to the platforms for this purpose.

· Initially, due to the lack of domestic capability in this area, the National Aircraft Carrier will not feature a catapult system. However, the ship's design will include a Modular Ramp System, and if domestic catapult production becomes possible in the future, this modular ramp can be removed, and the flight deck will be converted into a flat structure for the integration of a catapult system. Space for the catapult is already allocated in the internal layout design of the National Aircraft Carrier in anticipation of this possibility.